ATI Q46S-66 Residual Sulfite Monitor

Construction:

Keep Chemical Costs Under Control!

Dechlorination of wastewater effluent is common practice in many wastewater treatment facilities throughout the U.S. Strongly reducing sulfur compounds are used to eliminate chlorine residuals that might prove toxic to fish in the receiving stream. Because residual chlorine discharge limits are often very close to zero, water quality monitoring residual values to comply with regulations has become very difficult, and controlling residuals at values between zero and 10 or 20 parts-per-billion is often not achievable. To meet stringent discharge limits, the sulfite or bisulfite used for dechlorination is added in slight excess, providing a small sulfite residual to ensure complete dechlorination. ATI’s Model Q46S/66 provides operators with a reliable tool for maintaining a small sulfite residual while reducing excess chemical consumption due to overfeed.

A Gas-Phase Approach to Sulfite Measurement

THEORY OF OPERATION

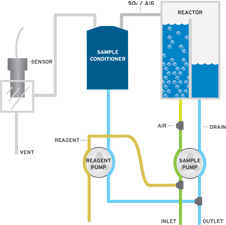

Because measuring the SO3= ion in solution is relatively difficult, the Q46S/66 Monitor takes a different approach to the measurement, employing a unique gas-phase method to continuously monitor sulfide without contact between the sensor and the water sample. In operation, a small amount of sample is pumped into the system and mixed with acid. In acidic solution, the sulfite ion is converted to sulfur dioxide gas as follows:

SO3= + 2H+

The mixed sample flows into a special chamber where the sulfur dioxide is stripped from the sample. A gas conditioning module prepares the gas sample for measurement prior to contact with a special SO2 gas sensor designed for the system. Sensor signals are amplified and displayed on a large-format, backlit LCD display in the Q46S electronics unit.

| |

PRODUCT FEATURES

Sulfite Measurement

Sulfite ion is measured selectively by conversion to sulfur dioxide.

Gas Phase Sensing

Measurement is made without contact between sample and sensor, eliminating the potential for sensor fouling.

Chemistry Module Power Options

Power options include 115 or 230 VAC, 50/60 Hz.

Three Control Relays

Relays are programmable for setpoint, deadband, and time delay.

Sample Line Cleaning

Internal sequencing and relay system for automated sample line cleaning.

Digital Communications

Communication options for Profibus-DP, Modbus-RTU, or Ethernet-IP.

Download

Download